Test Post

- Julia Elkouby

- May 5, 2022

- 2 min read

Designing and Building to Help Save Lives

Calcification of heart valves is one of the biggest killers in the world. Aortic Heart valve relacements however are only designed to last a limited number of years so research in this area is very important and could save many lives.

What I did...

I worked on the second prototype of the aortic valve bioreactor with Dr Torii at UCL. This bioreactor was built to help researchers observe how heart valves calcify and test them easily. It was designed to mimic biomechanical conditions and developed as an effective, customisable and affordable tool in heart valve research.Therefore a viewing window was implemented. I also improved the software interface so that it was easy to understand. I also made the pressure of aortic valves through narrowing of tubing and made it modular and flexible so it was easy to customise depending on the experiment. EVerything was manufactured in house using 3D printers and laser cutters. Pictures and videos of it see below. For the full report download below.

How It Works...

This machine works by pumping water through the valve whilst simulating the heart conditions. This simulation of the heart conditions was done primarily through the power of the pump as well as the pressure of the fluid above the valve. This pressure was customiseable by changing different tubings so that both aortic and eventually other valves could be tested. The water that circulated was also heated in the tank using cartridge heaters to make simulate body temperature. The tubings went off to the side to allow researchers to have a clear view of the valve so that they could observe the calcification of it and maybe even film it.

Project Photos...

Skills I used...

LabVIEW Programming

The whole program was done on LabVIEW. This is a graphical programming language that is used mainly in the medical devices field. The advantages of this language is that it can produce an interface easily and can simplify collecting data quickly.

CATIA (CAD)

CATIA is a CAD (Computer Aided Design) software that is used throughout the industry. It has many features and this particular project was fully designed on it.

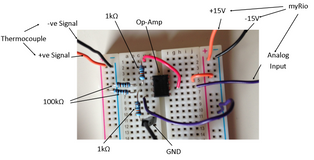

Electronics

Electronics were used in this project to connect all the various components and be able to collect data on the aortic valve that was being tested and check that it was performing the right things.

Laser Cutting

The whole machine was made using acrylic that was laser cut in the right shapes to easily put the machine together. This was done using standard laser cutters at UCL and using the sketches made on CATIA from the design model.

3D printing

3D printers were used for the smaller hard to manufacture parts. This was useful to get an accurate model that responded specifically to the design. CATIA model was used to create the design which was then 3D printed.

.png)

Comments